LATEST PROJECTS

Project | 01

Phase-change (liquid boiling) heat transfer of micro-nano structured surfaces

-

Conducted phase-change cooling experiment

-

Performed the high speed imaging to capture bubble dynamics

-

Successfully improved the heat transfer performance copper surfaces by growing CuO nanostructure through chemical oxidation

-

Performed automated data acquisition and data analysis to characterize the heating performance

Project | 02

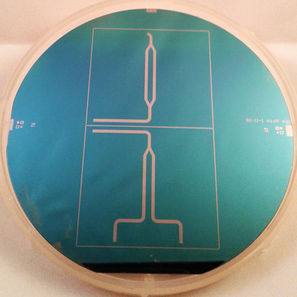

Development of counter-flow microfluidic devices for thermal stability in microfluidic reactors

-

Designed, fabricated, and tested microfluidic thermal devices

-

Applied photolithography, silicon wet etching (KOH), wafer bonding, and inlet/outlet PDMS port attachment (Oxygen plasma bonding) for Glass/silicon devices

-

Applied rapid prototyping (xurography) for fabrication of Glass/Glass and Glass/Quartz microfluidic devices

-

Compared the thermal performance of direct-flow and counter-flow microfluidics at various flow rates

-

Achieved impressive thermal ramp rate (150 K/s) using counter-flow design

-

Proposed the counter-flow as a way to overcome the thermal instabilities in microfluidics

Project | 03

Design analysis and structural-electrical FEA of a 3D printed liquid metal strain sensor

-

Obtained the Hyperelastic material model (Mooney-Rivilin) model of the 3D printed material (TPU) from uniaxial tensile test

-

Simulated the Structural and Electrical performance of the sensor in COMSOL and validated the models against experimental results

-

Conducted a parametric study on geometrical aspects (substrate thickness, liquid metal channel cross section, channel pattern, ...) and material aspects of the sensor to provide a guideline for the highest sensitivity in such sensors

Project | 04

Automated Image processing of the high speed videos for extracting the bubble features

-

Developed an algorithm for finding the average departing bubble diameters in MATLAB and obtained the average bubble diameters for different heat fluxes

-

Developed an algorithm for counting the bubbles in each frame in MATLAB and obtained the average bubble diameters for different heat fluxes

-

Applied preprocessing including Gaussian smoothing, FFT for removing the fin background fins, Morphological (tophat, bottomhat) to enhance the foreground bubbles and attenuate the background

-

Applied Edging (Prewitt), binarization (Otsu method), Morphological operations (closing, opening, filling) and used Circular Hough Transform for detecting the circular bubbles and finding the diameters

-

Removed the false positives using the glowing bright spot of the bubbles as a corrector

Project | 05

Parametric study for optimization of a continuous flow thermoelectric sensor

-

A continuous-flow y-shaped microfluidic sensor was fabricated and modeled

for optimum performance -

Exothermic mixing of water and ethanol was modeled using a UDF in ANSYS Fluent to incorporate a nonuniform heat source detected by thermoelectric sensor

-

Simulation is validated for concentration and temperature against experimental data

-

Various ratio of water/ethanol and flow rates were simulated to find the optimum location

-

Guidelines are established for the sensor placement in these types of the devices