Expertise in design, fabrication, test, analysis, and simulation of MEMS sensors and Microfluidics

-

Hands on experience in Class 100 Cleanroom for these processes: Wafer cleaning (RCA, nanostrip, oxygen plasma), Dry oxidation, Photolithography (Positive and negative photoresists), spin coating, Wet chemical etch (anisotropic etch of silicon, Isotropic etch in BOE), RIE,

-

Experience in wafer dicing (silicon, glass quartz), through hole via, wafer bonding (adhesive), device packaging, oxygen plasma bonding (PDMS to glass/silicon)

-

Hands-on experience in characterization using SEM, 3D confocal scanning microscope (VK-100), Optical microscope, thin film measurement (Filmetrics), surface profilometer (Dektak 150)

Expertise in using low-cost rapid prototyping techniques for developing Microfluidics:

-

Soft (mold) lithography for PDMS devices

-

Xurography (cutting plotter) for fabricating complex microfluidics with layers of glass/silicon, quartz, ... and Kapton adhesive layer

-

Design of the microfluidic layouts in Adobe Illustrator, AutoCAD, and L-edit

-

Expert in CFD and FEA tools

-

ANSYS-Fluent for heat, flow, and mass problems- Expert in batch-mode simulation using Journal and scheme programing, expert in developing User Defined Functions in C language

-

COMSOL Multiphysics (MEMS, microfluidics, non-linear Module, Structural, Electrical) for simulating sensors

-

SolidWorks (parametric study, rapid heat transfer evaluation

-

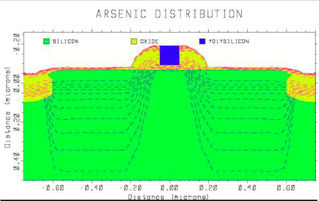

TCAD for semiconductor process simulation

-

CAD tools including:

SolidWorks, AutoCAD, ANSYS SpaceClaim, GD&T knowledge

-

Automated data acquisition in LabVIEW

-

Developing numerical analysis codes (Finite Element Method, Finite Volume Method, and Finite Difference Method) in FORTRAN and MATLAB

-

Image Processing in MATLAB

-

Knowledge of FMEA, SPC, control charts, quality control, lean manufacturing, DMAIC, MSA, root cause analysis, process and product development, process capability analysis, KAPA, and GR&R

-

Data analysis in Minitab, MATLAB, and Microsoft EXELL